VQT6UR

Barrel End Mill for Finish Cutting of Titanium Alloys

New Successive Two Radius Design Achieve High Efficiency Machining

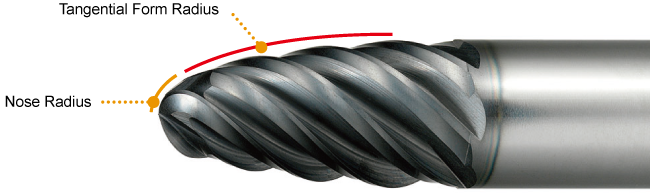

Nose radius suitable for fillet milling, also tangential form radius fit composite blade surface machining.

Ideal Shape

Compared with ball nose end mill, an tangential form radius is larger and cusp height is controllable.

This design makes highly efficient machining with larger pick feed.

Nose and tangential form part has two different radius.

Shorter cutting distance contribute to longer tool life.

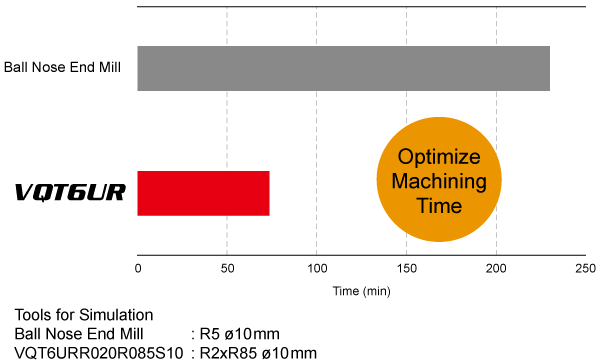

Comparison of Machining Time by CAM Simulation

Cutting Performance

Slot Milling of Titanium Alloy

Provided good surface finishes and there was no chipping on the cutting edge.

Deep Wall Machining of Titanium Alloy

High efficiency machining is possible while maintaining quality of machined surface.

Machining Example

Blade Surface Machining

Fillet Milling

Technical consultation from here

24/7Contact form

Japan

Japan United States

United States Mexico

Mexico Brazil

Brazil EU

EU United Kingdom

United Kingdom Germany

Germany Spain

Spain France

France Italy

Italy Poland

Poland Turkey

Turkey Czechia

Czechia China

China South East Asia, Oceania, South Africa

South East Asia, Oceania, South Africa India

India