-

1. Milling is interrupted machining in which the cutting edge is subjected to severe thermal shock. This is due to what reason?

ADue to the fact that the cutting edge is always in continuous contact with the cutting edge. BThe rapid temperatures increase due to friction during the cut and rapid cooling as this cutting edge disengages from the workpiece. -

2. Face milling cutters are divided into the 2 groups. Plain milling cutters and shoulder milling cutters. Which of the following is correct?

APlain milling cutters have a lead angle of less than 90°, whereas shoulder-milling cutters have a lead angle of 90°. BPlain milling cutters have a lead angle of more than 90°, whereas shoulder-milling cutters have a lead angle of 90°. CPlain milling cutters have a lead angle of less than 90°, whereas shoulder-milling cutters have a lead angle larger than 90°. -

3. When carrying out milling that does not require a right angle then a plain milling cutter is the most suitable. What is the reason for it being the most suitable?

AMore cutting edges can be used making it more cost effective. BPlain milling cutters can be used with external coolant offering longer tool life. CA larger corner angle is used this generates thinner chips, reducing cutting resistance and increasing tool life. -

4. When should extra-fine pitch face milling cutters be used?

AWhen higher machining efficiency is required when machining materials that generate long chips. BWhen higher machining efficiency is required when machining materials that generate short chips. CFor the machining of stainless steels. -

5. There are 2 machining methods, up cut and down cut milling. Which of the following is incorrect?

ADown cut milling offers longer tool life than up cut milling. BDown cut milling is a method of machining in which the direction of the cutter rotation and feed direction are in the same direction. CUp cut milling is a method of machining in which the direction of the cutter rotation and the feed direction of the workpiece are in the same direction. -

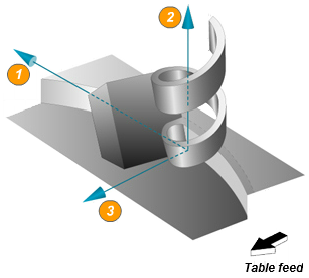

6. Which forces are shown in the diagram?

AFeed, back, and principal force. BPrincipal, back, and feed force. CBack, feed, and principal force. -

7. What occurs as the number of flutes for an end mill increases?

AThe overall tool rigidity increases. BThe overall tool rigidity decreases. CThe overall chip disposal properties increase. -

8. What occurs when the number of flutes of an end mill decreases?

AThe overall chip disposal properties increase. BThe overall chip disposal properties decrease. CThe overall tool rigidity increases. -

9. A roughing edge end mill is used for what type of machining?

AOffers a wavy cutting edge that breaks up the chips, leading to lower cutting resistance. BIt is ideal for finishing due to the low cutting resistance. CIt is ideal for roughing but cutting resistance is high. -

10. Square end mills that have a centre holes can be used for?

ASlot milling and side milling. BCopy machining. CBoth horizontal and vertical feed machining -

- Next

- Try again

Result