IMPACT MIRACLE REVOLUTION

For Machining of Hardened Steels

Revolutionary Machining of Hardened Steels

New coating provides outstanding tool life

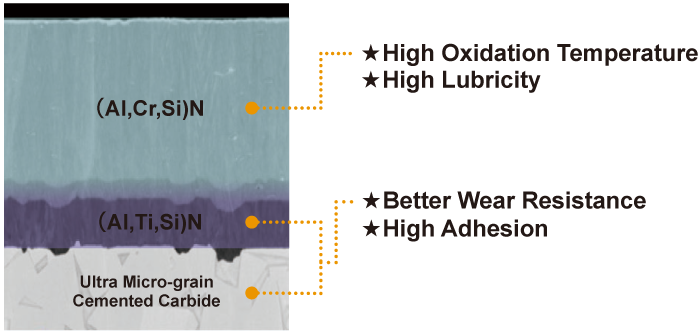

IMPACT MIRACLE REVOLUTION Coating

The combination of the newly developed (Al, Cr, Si) N coating with improved lubricity and a high oxidisation temperature, together with the (Al, Ti, Si) N coating layer that displays excellent wear and adhesion to other coating layers, enables efficient and reliable machining of hardened steels.

Due to manufacturing adjustments, differences in the color of the coating for different diameters may occur. This has no adverse effect on performance.

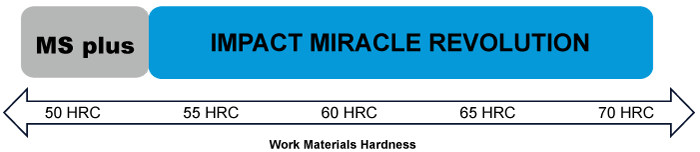

Selection According to Work Material Hardness

Precision-Corner Radius End Mill, 4 Flute

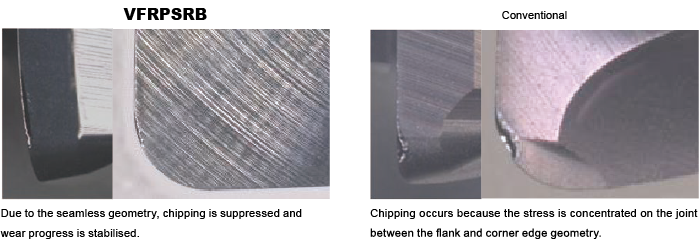

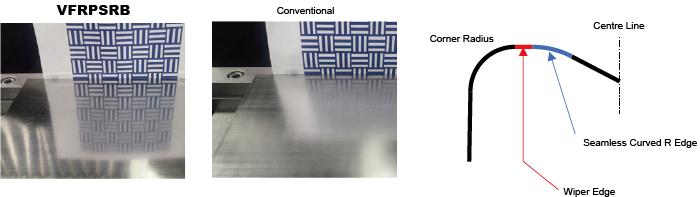

VFRPSRB

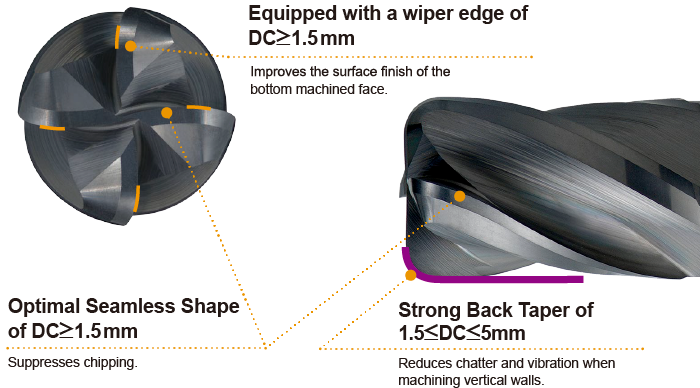

A seamless edge geometry that is resistant to chipping, together with a wiper edge and strong back taper enables high precision machining.

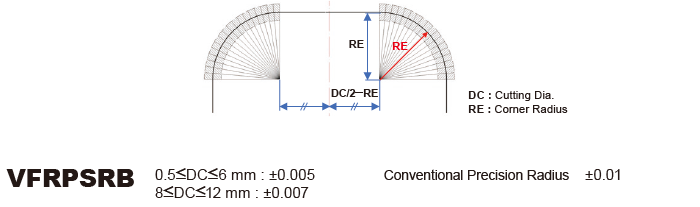

High-Precision Corner Radius Accuracy

The corner radius of VFRPSRB is measured as follows, based on the absolute centre of the corner radius.

Completely Seamless Curved R Edge, DC≥1.5mm

A stable machined surface is achieved by a seamless blend between the radius and flank geometry.

Equipped with a Wiper Edge, DC≥1.5mm

A smooth surface finish is possible by installing a wiper edge.

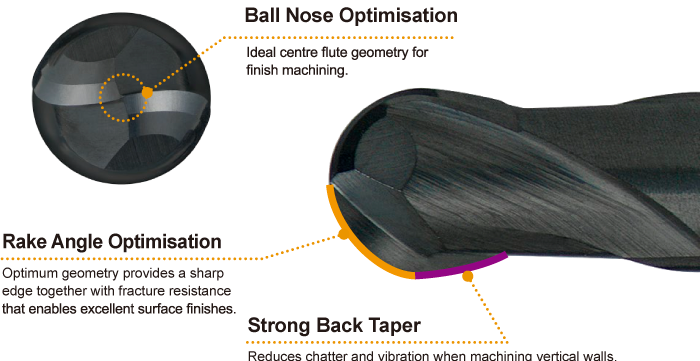

Ball nose, 2 Flute, Long neck

VFR2XLB

Precise machining of vertical walls is possible due to a back taper and a strong, seamless ball nose cutting edge geometry.

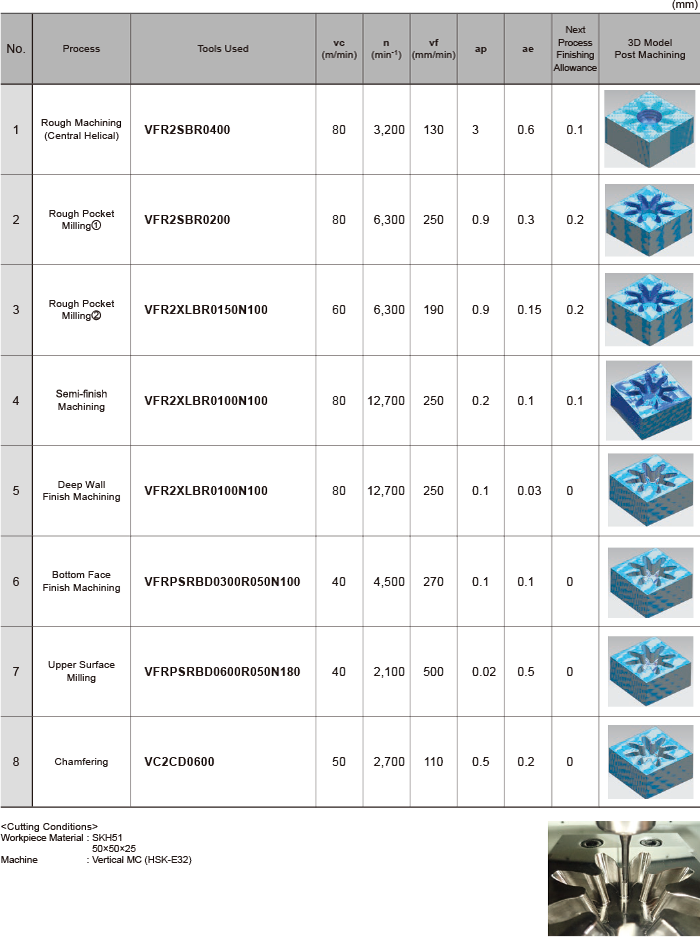

Machining of a Bevel Gear Mould

Ideal for machining high-hardness precision, cold forging moulds of 65HRC or higher.

Revolutionary Hardened Steel

VFR2SSB / VFR2SB

2 Flute Ball Nose End Mill

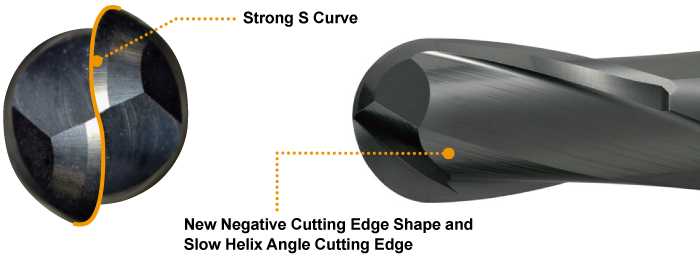

New Cutting Edge Shape: Optimization of the cutting edge curve, helix angle, and rake angle have improved the edge strength at all areas of the ball blades.

Carbide Substrate: High-grade material types ideal for high-hardness materials.

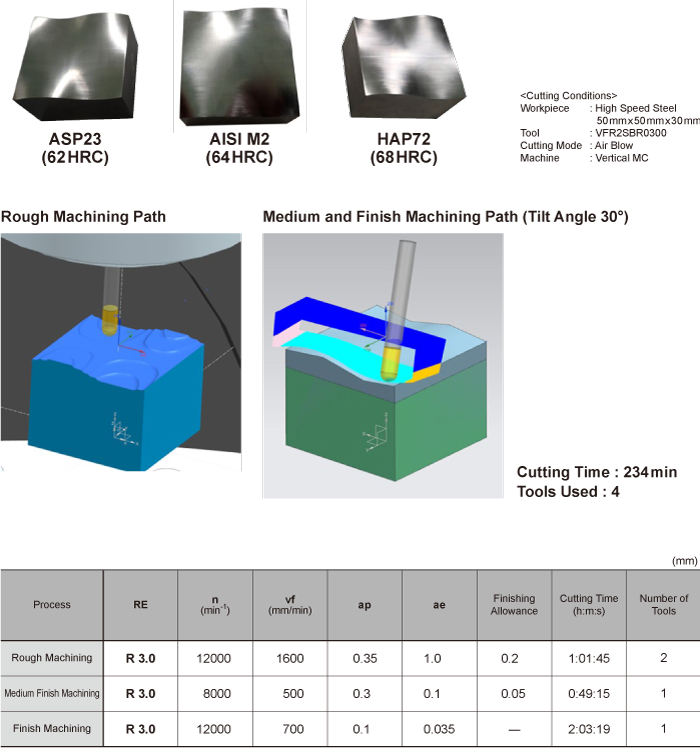

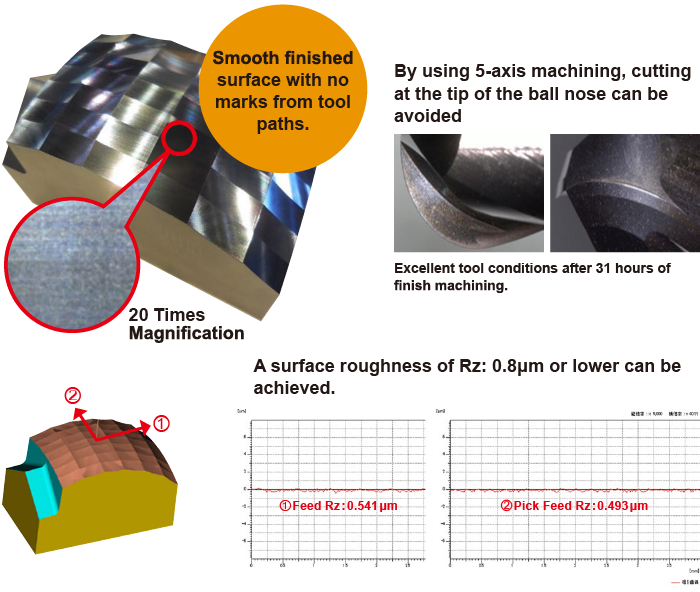

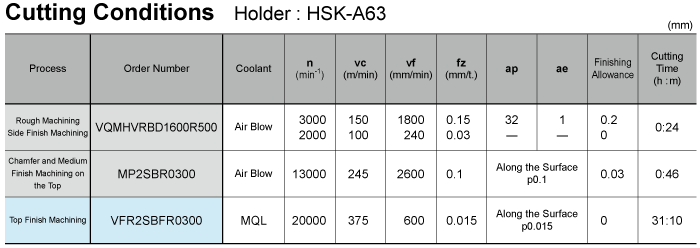

Cutting Example

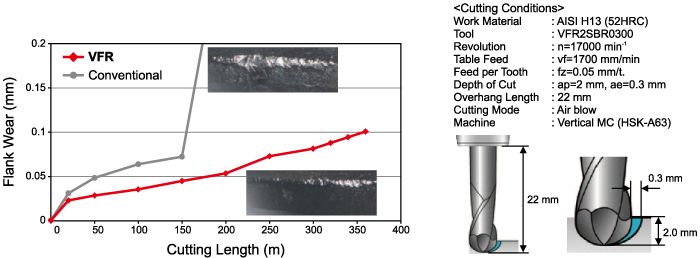

Cutting Performance

AISI H13 (52HRC)

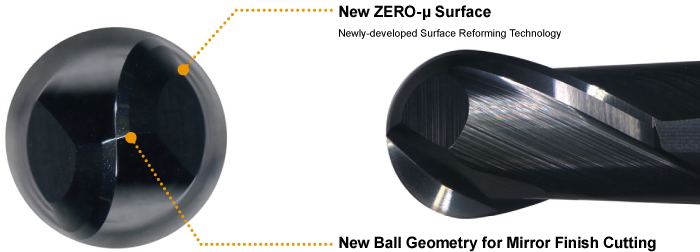

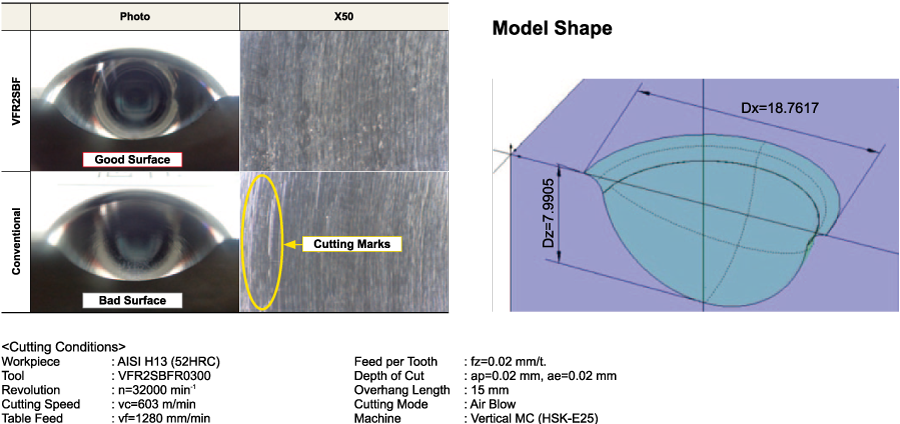

VFR2SBF

2 Flute Ball Nose End Mill for Mirror Finish Cutting

Application Example

Work Material : Pre-hardened Steel

AISI H13 (52 HRC) Comparison of Machined Surface

Technical consultation from here

24/7Contact form

Japan

Japan United States

United States Mexico

Mexico Brazil

Brazil EU

EU United Kingdom

United Kingdom Germany

Germany Spain

Spain France

France Italy

Italy Poland

Poland Turkey

Turkey Czechia

Czechia China

China South East Asia, Oceania, South Africa

South East Asia, Oceania, South Africa India

India