AXD4000A

For Ultra-high Speed, Super Efficient Machining of Aluminium Alloys

Up to 5000 m/min cutting speed.

10000cm3/min metal removal rate is possible.

(300km/h=33000min-1 x ø50mm)

Feature

How to Choose AXD4000A or AXD4000

AXD4000A is specifically engineered for continuous high-speed and ultra-high-speed machining of aluminium alloys, and can be better utilised on more powerful machines with more than an 80kw motor.

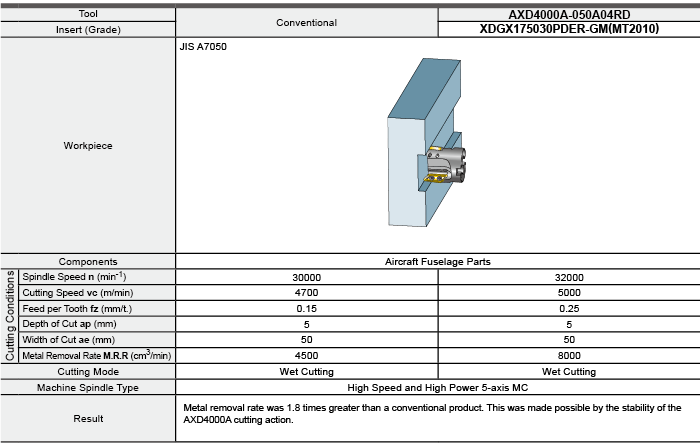

Cemented Carbide Grade for High-speed Processing of Extra Super Duralumin and Aluminium / Lithium alloy

MT2010

A high grade cemented carbide suitable for ultra-high speed machining at cutting speeds of 5000m/min, combined with excellent wear resistance and toughness.

Cutting Performance

Al-Li Alloy : Comparison of Wear Resistance

Selection of Insert

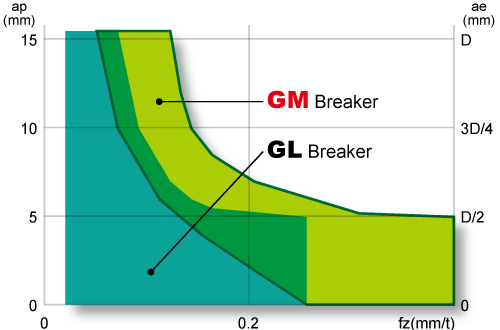

It is necessary to choose the best insert according to the cutting conditions. Please select an insert from the tables below.

1st recommendation for High Efficiency and High Load Machining on High-speed Spindles is the GM breaker with a strong cutting edge.

Selection of insert according to the feed per tooth and the required cutting depth

Selection of insert according to the width of cut and the required cutting depth

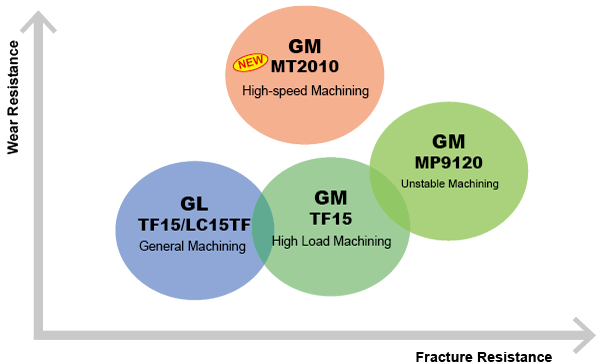

Selection of Insert According to Cutting Edge

Selection of insert according to wear resistance

Application Examples

Technical consultation from here

24/7Contact form

Japan

Japan  United States

United States  Mexico

Mexico  Brazil

Brazil  EU

EU  United Kingdom

United Kingdom  Germany

Germany  Spain

Spain  France

France  Italy

Italy  Poland

Poland  Turkey

Turkey  Czechia

Czechia  China

China  Asia Pacific

Asia Pacific  Vietnam

Vietnam  Indonesia

Indonesia  India

India