MC6100 Series

CVD Coated Grade for Steel Turning

Bringing the Ultimate High Speed

Cutting Performance

CVD Coated Grade for Steel Turning MC6115 / MC6125 / MC6135

Dramatic increase in stability and wear resistance, enabled by utilising the improved coating adhesion and crystal orientation technology.

The addition of positive and negative inserts enables a wide range of machining such as boring and finishing.

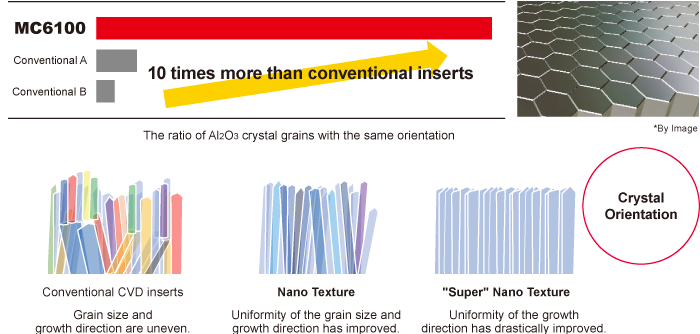

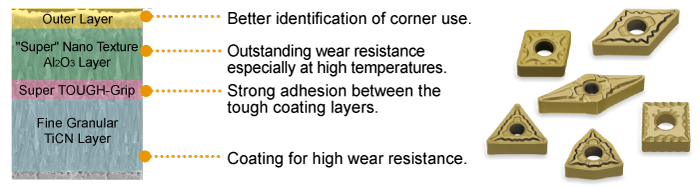

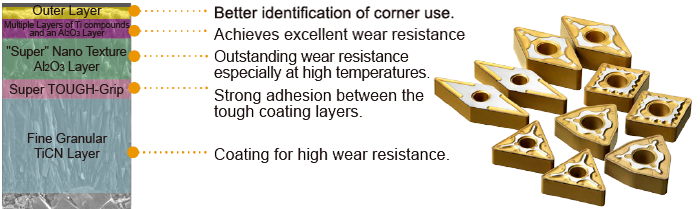

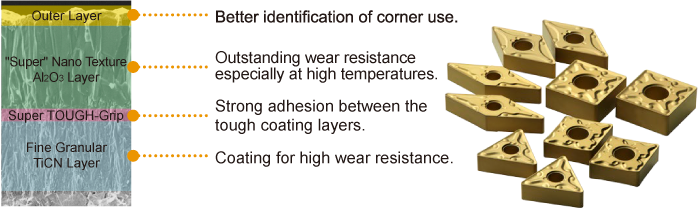

"Super" Nano Texture Technology

The standard Nano Texture Technology has been improved and developed to be an industry leading standard for crystal growth of Al2O3 coatings. This Super Nano Texture Technology increases tool life and wear resistance due to the fine, dense crystal growth process.

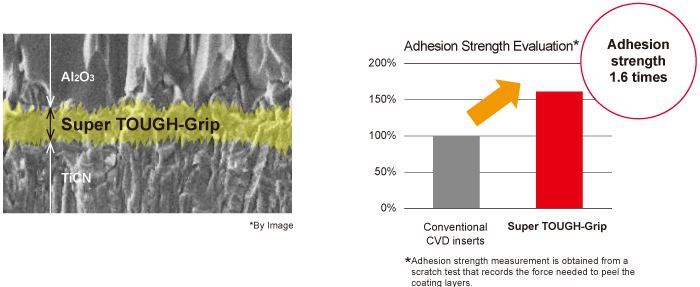

Super TOUGH-Grip

The Super TOUGH-Grip layer has finer crystal grains that enhance the strength of the adhesion between the coating layers.

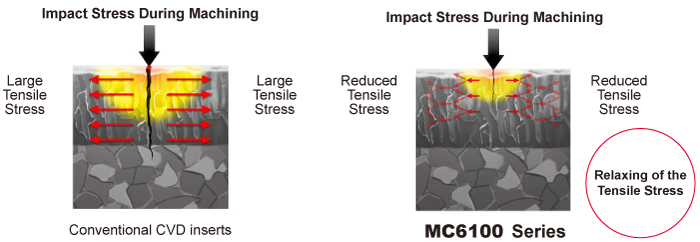

Protection Against Sudden Fracturing

Cracks that occur during unstable machining are prevented due to the relaxing of the tensile stress in the coating. MC6100 series has an 80% reduction in coating tensile stress compared to conventional CVD inserts.

Cracks are generated in the surface of coatings during machining. They propagate through the coating into the substrate due to the large tensile stress in the coating structure. This creates one of the main causes of sudden insert breakage.

MC6100 Series has a much lower level of stress than conventional CVD coatings due to the surface treatment. This divides the force of impacts during machining and protects from sudden fracturing.

MC6135

Optimal versatility for machining continuous through to intermittent applications.

Thinner Coatings Optimised for General Purpose Machining

Industry-leading crystal orientation control technology enables thinner but still impact-resistant coatings provide improved chipping and wear resistance which is optimal for general-purpose use. (50% thinner compared to our conventional coating).

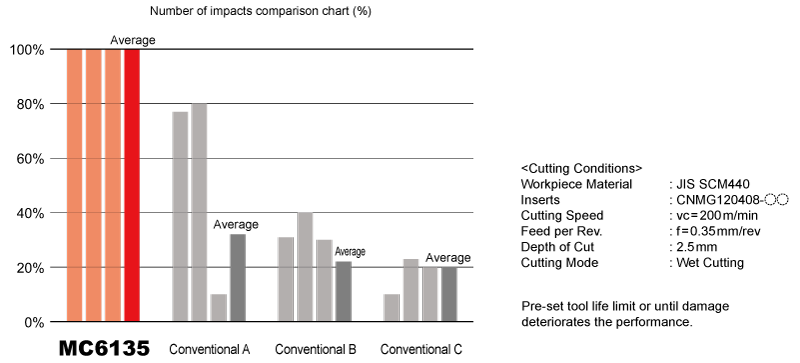

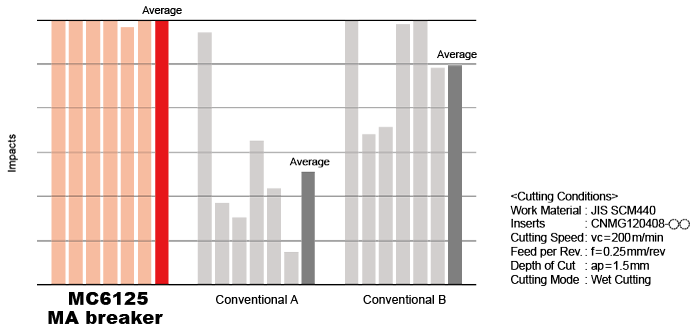

Machining SCM440 : Comparison of Toughness During Interrupted Cutting

MC6135 shows high stability even during interrupted cutting and can be used over a wide area of applications.

MC6125

First recommended grade for steel turning.

Increasing tool life with stable performance over a wider range of applications.

Special Smooth Surface Treatment

MC6125 uses a new surface treatment for the cutting edge for increased stability. Additionally, the seating faces also have a special smooth surface treatment that provides improved clamping stability to enable a wider range of applications.

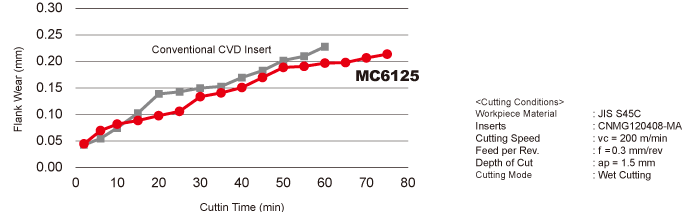

Machining S45C : Comparison of Wear Resistance

The surface treatment has improved stability and provided longer tool life.

MC6115

MC6115 improves high speed machining and process efficiency with a dramatic increase in resistance to wear and heat.

Improved Outer Coating (Layer)

The outer layer of MC6115 restricts chip welding thereby improving the dimensional accuracy and surface roughness of components. This also enables easy recognition of whether the corner can continue machining.

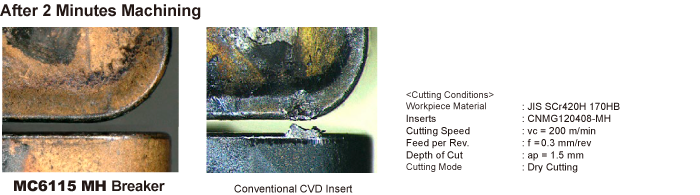

Example when machining Scr420H

When comparing the high edge strength MH breaker with a conventional low resistance chip breaker, it shows that MC6115 accomplishes both high welding and wear resistance.

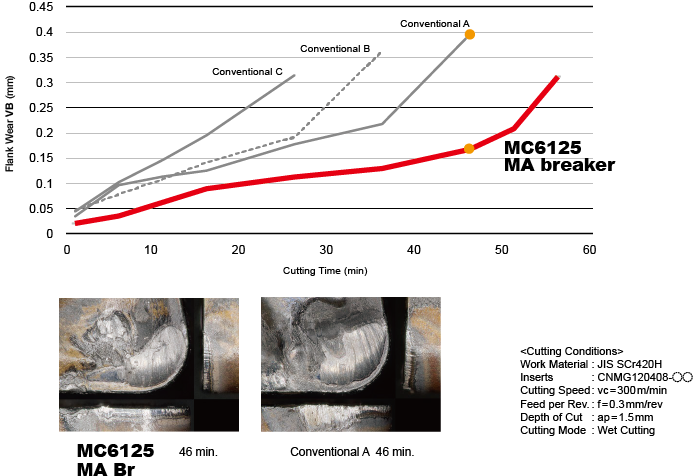

Machining SCr420H : Comparison of Wear Resistance During Continuous Wet Cutting

The thick coating exclusively for MC6125 highly suppresses early wear.

Comparison of Toughness During Interrupted Cutting

Provides stable cutting under severe cutting conditions that are likely to cause sudden fracturing.

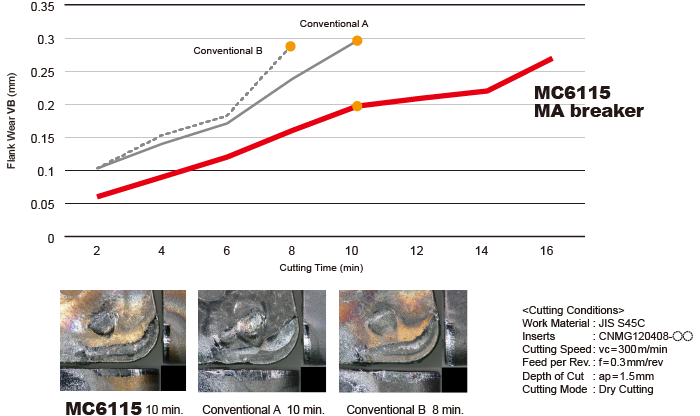

Machining S45C : Comparison of Wear Resistance During Continuous Dry Cutting

The "Super" Nano Texture Technology increases tool life even when dry cutting by suppressing crater wear.

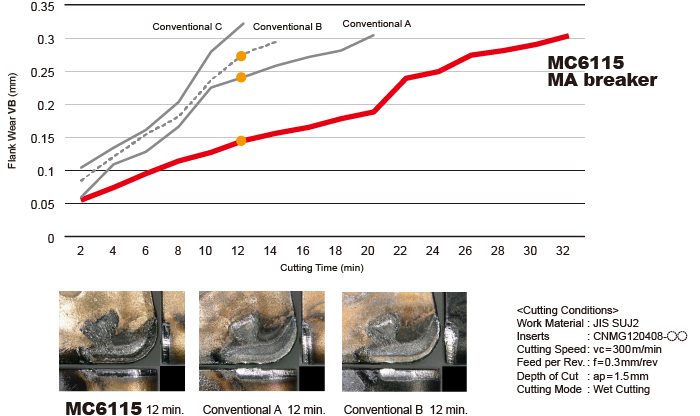

Machining SUJ2 : Comparison of Wear Resistance During Continuous Wet Cutting

The thick coating provides high flank wear resistance.

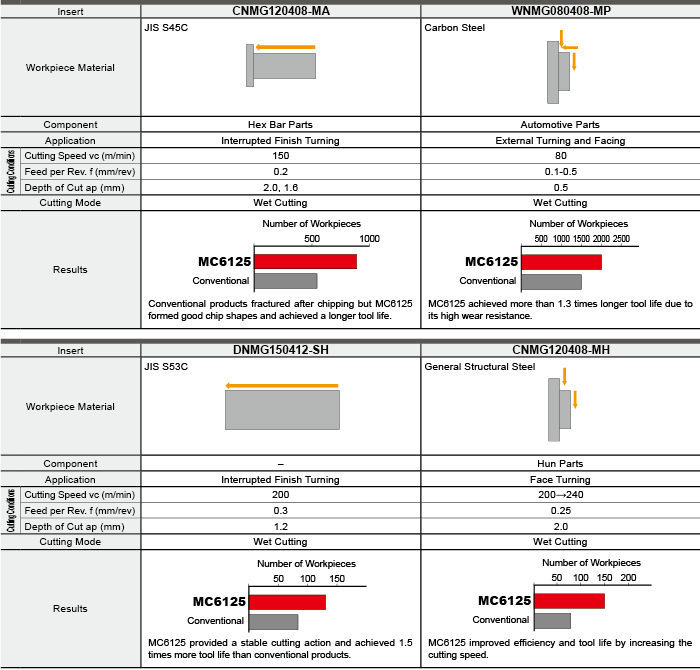

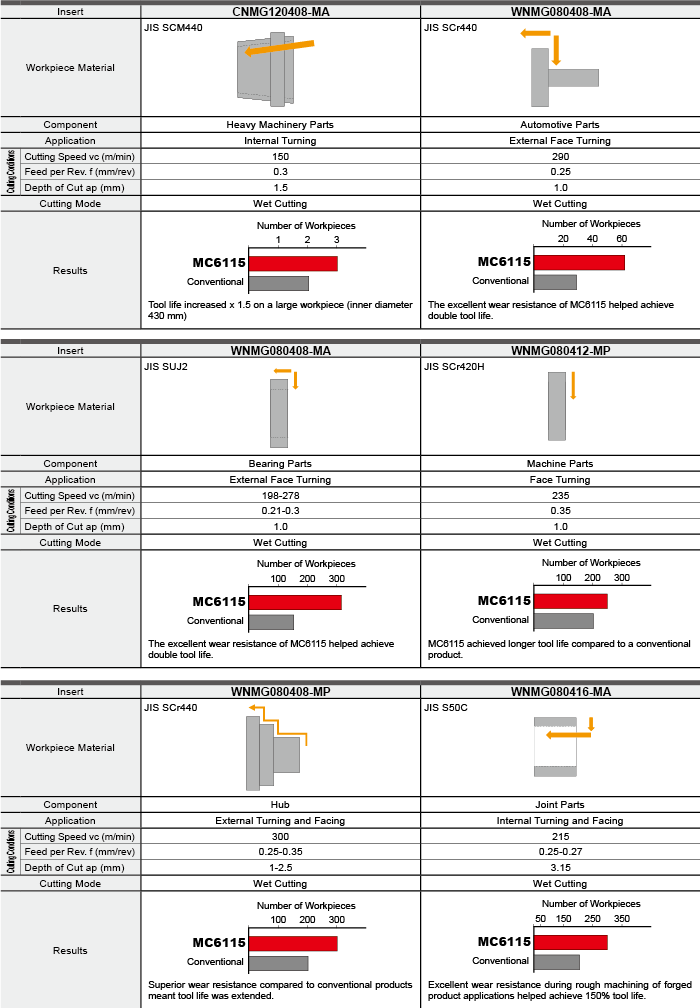

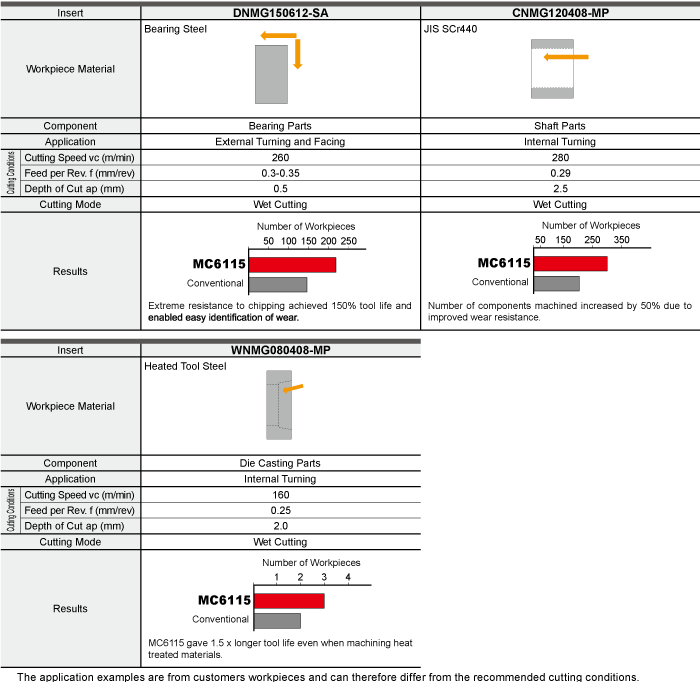

Examples of Usage

Technical consultation from here

24/7Contact form Japan

Japan United States

United States Mexico

Mexico Brazil

Brazil EU

EU United Kingdom

United Kingdom Germany

Germany Spain

Spain France

France Italy

Italy Poland

Poland Turkey

Turkey Czechia

Czechia China

China South East Asia, Oceania, South Africa

South East Asia, Oceania, South Africa India

India