BC8200 Series

CBN Grade for Turning Hardened Steel

New Coated CBN Grades for the Modern Methods of Turning Hardened Steels

BC8210 For Continuous and Light Interrupted Cutting

Outstanding Tool Life with High-speed Machining

Suitable for continuous cutting and Light interrupted cutting. BC8210 exhibits excellent chipping, flank and crater wear resistance, thereby providing a stable machining process at high speed cutting conditions.

Comparison of Wear Resistance During Continuous Cutting

Defects due to crater wear are suppressed and tool life is improved compared to conventional products.

BC8220 General Applications

Achieves Impressive Tool Life Over a Wide Range of Cutting Conditions.

Highly suited to a wide application area from continuous through to heavy interrupted cutting. It also has excellent crater wear and fracture resistance due to the new CBN base material and together with a new coating dramatically extends tool life.

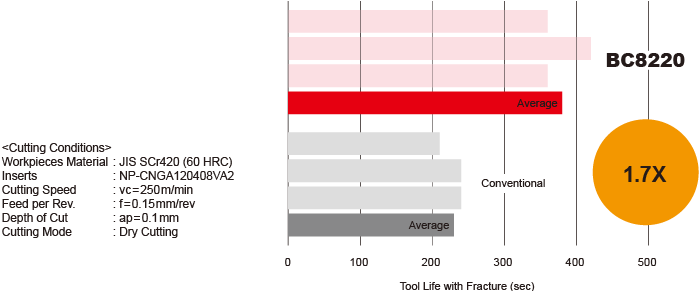

Comparison of Fracture Resistance During Medium Interrupted Cutting

Excelling in suppressing chipping and cracks, it also improves fracture resistance after crater wear that provides a stable cutting action that improves tool life.

Optimised Substrate Technology with Ultra Micro-particle Binder

The ultra micro-particle binder prevents linear crack development to avoid sudden fracturing.

Positive Effect of the Newly Developed Heat Resistant Binder

By increasing the heat resistance of the binder, wear resistance due to the deterioration of the binder

component is increased, thereby suppressing crater wear, chipping and fracturing.

Area of Application

Chip Breaker

The new BL chipbreaker provides good chip control at medium to light depths of cut.

A versatile range of chipbreakers are available for a wide range of applications.

BL Chipbreaker (BC8220)

It exhibits excellent chip control performance at cutting depths of 0.2 to 0.6 mm.

Combined with the dedicated honing, a low resistance cutting edge is created that suppresses chatter and

vibration.

BR Breaker (BC8220)

A reduced number of passes needed and improved chip control during high depth of cut.

Chips are formed with the effect from the rake angle, and the multi stage breaker wall supports a wide range of cuts.

Recommended Cutting Conditions : vc=80-200 m/min, f <0.3 mm/rev, ap=0.6-1.0 mm

BF Chipbreaker (BC8210, BC8220)

Achieves excellent chip control when finish cutting at depths of 0.3 mm or less.

Recommended Cutting Conditions : vc=80-200 m/min, f <0.3 mm/rev, ap=0.1-0.3 mm

BM Chipbreaker (BC8220)

Great chip control when machining at medium depths of cut. (0.3-0.8 mm)

Recommended Cutting Conditions : vc=80-200 m/min, f <0.3 mm/rev, ap=0.3-0.8 mm

Combination of BF Breaker and WS Wiper Insert

CNGM and DNGM types are now available with new inserts that combine a BF chip breaker with a WS wiper Insert. ( BC8210 : BF-oNGMooooooTSWS2, BC8220 : BF-oNGMooooooTAWS2 ) It is effective for chip control and improvement of finished surface roughness without worrying about the hand of the tool even when continuous external or internal turning and facing.

Edge Preparation (Honing)

In addition, a range of different honing types that can be used for various applications is available.

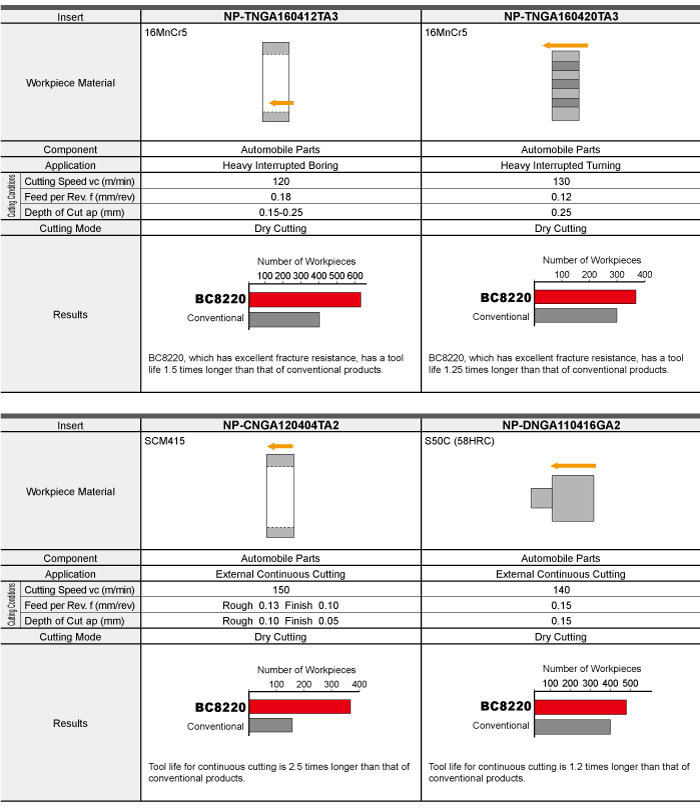

Examples of Usage

Technical consultation from here

24/7Contact form Japan

Japan United States

United States Mexico

Mexico Brazil

Brazil EU

EU United Kingdom

United Kingdom Germany

Germany Spain

Spain France

France Italy

Italy Poland

Poland Turkey

Turkey Czechia

Czechia China

China South East Asia, Oceania, South Africa

South East Asia, Oceania, South Africa India

India