MS plus End Mill Series

Carbide End Mills

Tough applications require ''Plus'' performance

(Al,Ti,Cr)N multilayer coating

Our original coating technology enables a multilayer of (Al,Ti)N and (Al,Cr)N. It allows machining of a wide range of workpiece materials.

Chamfer Cutter MP3C

New, long tool life cutter for highly efficient chamfer machining.

Highly Effective for Chamfer Machining

The 3-flute geometry achieves high feed and extended tool life, and the effects of the helical flutes suppress the occurrence of burrs chamfer machining.

DLE and GKCD type drills are recommended for centering.

S55C Comparison of Burrs After Chamfering

For Swiss-Type Automatic Lathes MS plus End Mill Series

MP2ES/3ES/4EC

Provides Stable Machining and Resists Edge Chipping Even when Overused

Comparison of Fracture Resistance - Machining SUS304

A round stainless steel bar is machined effectively due to the tough cemented carbide substrate and the gashed land providing improved fracture resistance.

SQUARE END MILLS

MPMHV / MPJHV

The irregular helix geometry reduces vibration to enable efficient machining of carbon and stainless components.

CUTTING PERFORMANCE

Comparison of surface roughness

Good surface with no chattering due to irregular helix.

Comparison of feed rate

Up to double the feed rate of conventional end mills.

RADIUS END MILLS

MPXLRB

Suitable for high precision and high efficient machining of die & mold.

Vibration control geometry is adopted for more than ø1 mm sizes.

4-flute is adopted in ø0.4‒6 mm sizes.

Cutting Performance

NAK80 High Quality Surface Finishes

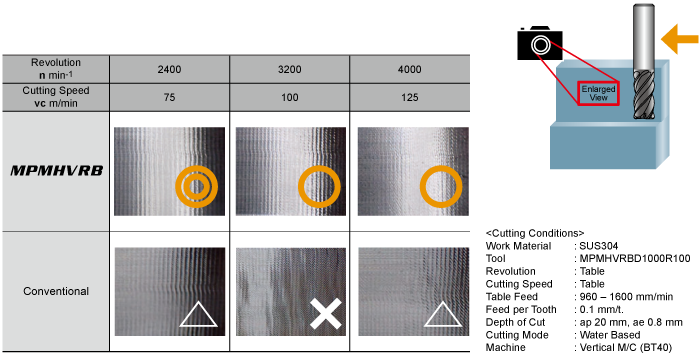

MPMHVRB

A high-efficiency 4-flute radius end mill with irregular helix flutes and a wide range of application.

Cutting Performance

AISI 304 Vibration Resistance Comparison

BALL NOSE END MILLS

MP2SDB

Tough carbide substrate with high chipping resistance.

Ideal for semi-finishing of forging dies.

CUTTING PERFORMANCE

Resistance to chipping

MP2SDB shows excellent chipping resistance even at large depths of cut,high feed rates and long overhang applications.

MP3XB

Ideal for rough milling of long overhang applications and semi-finishing of forging dies (40-50 HRC)

CUTTING PERFORMANCE

Resistance to chipping overhang length 40mm

Continued reliability when rough milling long overhang applications.

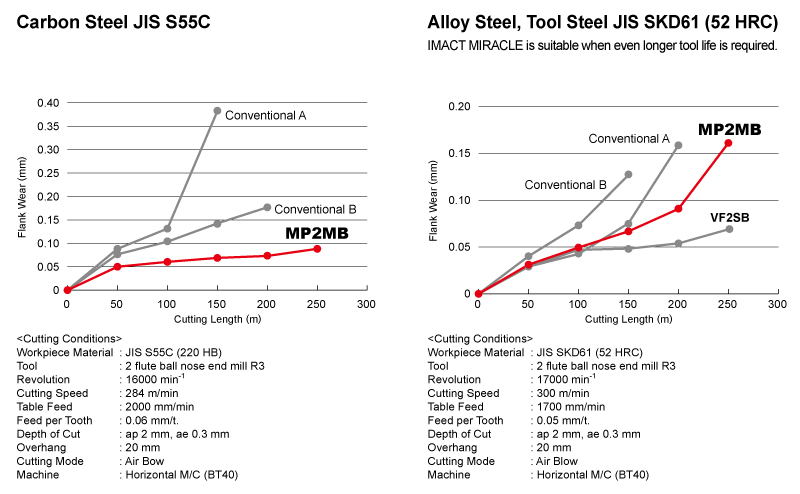

MP2SSB / MP2SB / MP2MB / MP2XLB

Greatly improved wear resistance even when machining hardened materials.

MS plus provides long tool life on materials up to 52HRC.

For steels harder than 52 HRC, IMPACT MIRACLE end mills are recommended. (TOOLS NEWS B075)

CUTTING PERFORMANCE

Excellent wear resistance compared to conventional products.

Technical consultation from here

24/7Contact form Japan

Japan United States

United States Mexico

Mexico Brazil

Brazil EU

EU United Kingdom

United Kingdom Germany

Germany Spain

Spain France

France Italy

Italy Poland

Poland Turkey

Turkey Czechia

Czechia China

China South East Asia, Oceania, South Africa

South East Asia, Oceania, South Africa India

India