iMX End Mill Series

Exchangeable Head End Mills

“Carbide(head)”+“Carbide(holder)”

Double face contact type

Features of BT30 Mono-Block Type Steel Holder

New tool holders for the iMX series.

High rigidity realises high efficiency machining

Benefits of Mono-Block Type Holders

The mono-block type holder greatly reduces tool overhang, allowing stable machining even with large diameter tools, achieving high efficiency machining.

When a standard milling chuck is used, a screw-in type shank also required. This is not needed when using a mono-block type holder, therefore a reduction in costs can be realised.

By undercutting the bottom of the neck, makes it suitable for vertical wall machining.

Cutting Performance

- Shoulder Milling Comparison in SUS630

Stable machining is achieved when combined with high-output machine tools.

Carbide holders and milling chucks are no longer required, and cost reductions can be realised.

- Side Milling Comparison in SUS304

Achieves high efficiency machining with a depth of cut (ae) that is three times that of a standard milling chuck holder.

Machining Example

-

Vertical Machining Centre : BROTHER INDUSTRIES, Ltd. S700Xd1

Achieved high efficiency machining with a metal removal rate of 600 mm3/min.

Spindle Speed Max. 10000 min-1 Spindle Motor 26.2 kW Torque 92 N·m

-

Horizontal Machining Centre : ENSHU, Ltd. SH350

When rough machining steel (S45C), a metal removal rate of 384 cm3/min was achieved, six times the recommended rate.

Spindle Speed Max. 12000 min-1 Spindle Motor 31 kW Torque 31.04 N·m

- Vertical Machining Centre : FANUC CORPORATION, α -D28LiB5ADV Plus Y500

When machining steel (S50C) grooves, no chatter vibration occurred and a finished surface roughness of Rz = 6μm was obtained.

Spindle Speed Max 10000 min-1 Instantaneous maximum torque 100 N·m (high torque spindle)

Features

The iMX series is a revolutionary end mill system that enables efficiency, high accuracy and rigidity by combining the advantages of both solid carbide and indexable end mills.

Security and rigidity close to that of a solid type end mill because the clamping faces are all carbide.

Excellent for reduced inventory over a variety of applications due to the exchangeable head.

Highly versatile grades

Tool life comparison when machining flat surfaces in Inconel 718

Comparison of tool rigidity

The double face contact of the carbide head and carbide holder gives an increase in rigidity of 30%.

Strength comparison when slot machining titanium alloy

The reliability of the screw fastening is significantly improved when compared to conventional that employ only steel fastenings. It is also able to cope with high cutting loads.

iMX New Type

Corner radius head with coolant hole, 6 flute, Irregular helix

iMX-C6HV-C High Efficiency Machining Enables Process Consolidation

Tool Integration Achieved

Multi functionality brings efficiency to the entire machining process.

Lollipop head with coolant hole, 4 flute

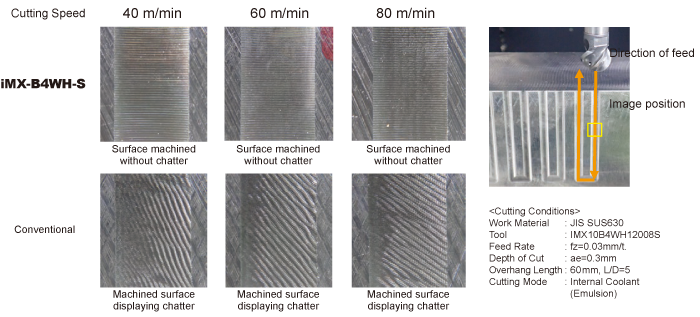

iMX-B4WH-S

SUS630 Comparison of Vertical Machining

iMX-RC4F-C For Titanium Alloys and Stainless Steels

A corner radius roughing type with a centre through coolant hole. The roughing edge geometry

reduces cutting resistance and is effective for low rigidity and long tool overhang applications.

EP8100 Series (EP8110 / EP8120)

The combination of the (Al,Cr,Si)N coating (newly-developed), which has a high oxidation temperature and high lubricity,together with the (Al,Ti,Si)N coating, which has better wear resistance and high adhesion, allows high strength hardened steel to be machined.

iMX-B3FV

iMX-B2S / iMX-B4S

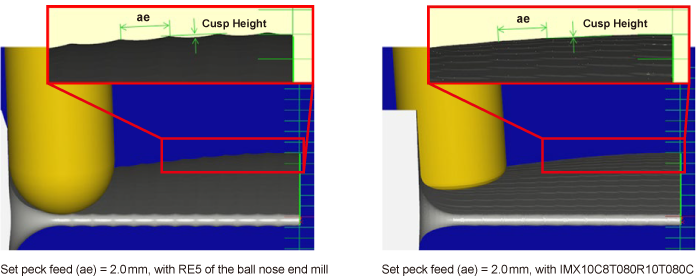

Corner radius, Taper head, Multi-flute, with coolant hole

Taper radius end mills, (corner radius) were conventionally used for turbine blade finishing. iMX taper radius end mills offer equivalent performance to solid end mills but achieve lower process costs.

Features

Drastically reduces cutting time

Reduces the cusp height when using the same pick feed (ae).

Chamfer Head

Features

Ideal geometry for different chamfering applications.

Steel Holder

Features

Series expansion of steel holders.

Series of cost effective and capable steel holders suitable for lower depths of cut and short overhang applications.

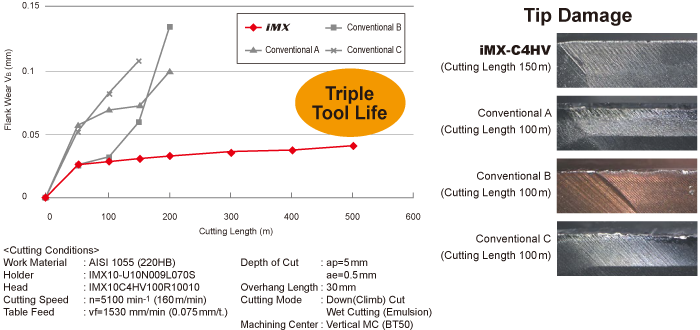

Cutting Performance

Tool life at least 3 times longer than conventional holders.

Duplex corner radius head with coolant hole, 4 flute, For high feed

iMX-C4FD-C

Features

High efficiency machining geometry

Thin chips and a long cutting edge combine to

provide both high performance and long tool life.

Vibration control geometry

Reduced cutting resistance in the radial direction

suppresses tool vibration and reduces deflection.

Cutting Performance

Tool Life Comparison when machining Cobalt Chromium Alloy (DC=10mm)

Tool Life (Co-Cr Alloy)

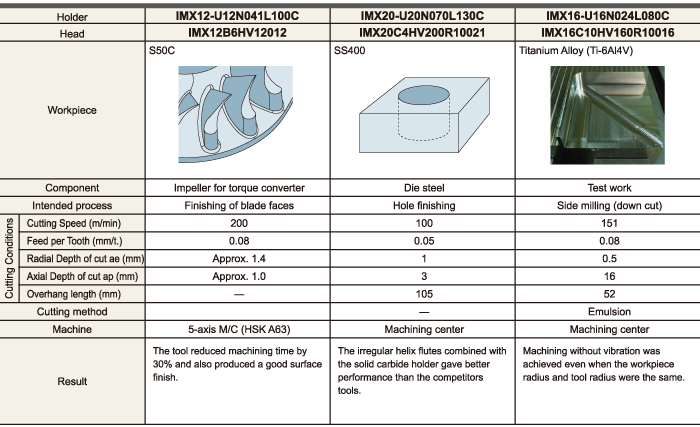

APPLICATION EXAMPLES

The examples shown are actual applications and can differ from the recommended cutting conditions.

Technical consultation from here

24/7Contact form Japan

Japan United States

United States Mexico

Mexico Brazil

Brazil EU

EU United Kingdom

United Kingdom Germany

Germany Spain

Spain France

France Italy

Italy Poland

Poland Turkey

Turkey Czechia

Czechia China

China South East Asia, Oceania, South Africa

South East Asia, Oceania, South Africa India

India