FMAX

High Feed Finish Milling Cutter for Aluminum Alloys and Cast Irons

Feed Maximum (FMAX) Milling cutter for ultra efficient and accurate finishing.

Environmentally Friendly Product

This product has been certified as an environmentally friendly product in the machine tool industry by the Japan Cutting & Wear-resistant Tool Association. This is a product unique to the industry, in harmony with the environment, and with the aim of fulfilling the social responsibilities of the machine tool industry.

FMAX DC≥80mm, general purpose insert

FMAX-LW for compact and smaller machining centres

Ultra High Efficiency Machining

The ultra fine pitch design is ideal for high efficiency machining of aluminium alloys. (vf ≥ 20000 mm/min).

The body protector on the rake face forms chip shapes ideal for disposal and disperses them away from the body. Internal coolant also aids this process. The body is compatible with all centre through coolant arbors.

Designed for High Speeds

Anti fly dovetail clamping mechanism.

Light Weight, High Rigidity Body

A special alloy steel and aluminium body combine to provide rigidity and light weight.

*1 Except DC=40, 50, 63mm

High Precision, Easy Setting

The combination of both large pitch and micro pitch screws provides precise run-out adjustment and for accurate placing of new or re-ground inserts within 5 μm or better.

Economy, Multi-use

CBN inserts for cast iron machining do not require regrinding (disposable type), making tool management easy.

PCD inserts for aluminium alloy machining have a maximum regrinding amount of 0.6mm on both the peripheral and bottom edges.

Coarse Pitch Type

By reducing the number of teeth finishing can be easily performed even if the machine or work material is not rigid.

Tool installation costs can also be reduced while maintaining the existing insert mounting and cutting edge adjustment functions.

For Compact and Smaller Machining Centres

It can be used for compact and smaller machining centres while maintaining the conventional insert mounting function and cutting edge adjustment function.

Features of the Inserts

CBN Grades for Milling Gray Cast Iron

General Purpose Inserts

CBN inserts for gray cast iron reduce the length of the wiper edge and provides excellent component surface finishes with low cutting forces.

CBN inserts for cast iron machining do not require regrinding because they are a disposable type.

PCD Grades for Milling Aluminium Alloys

General Purpose Inserts

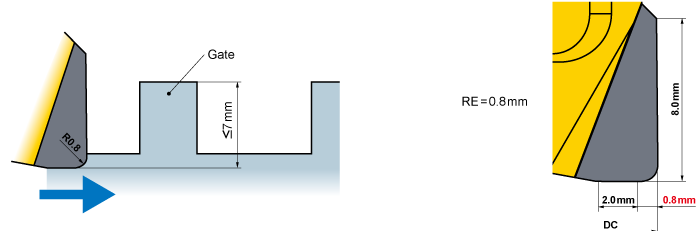

Inserts with corner R(RE) = 0.8 mm are excellent for general applications, and can be used in a wide variety of cutting areas.

They are able to exhibit outstanding cutting edge stability, particularly under high-load conditions such as heavy interrupted cutting.

The sharpness of inserts with corner R(RE) = 0.4 mm is one of their most notable features. Its effectiveness can be demonstrated by the ability to suppress chatter and maintain excellent finished component surfaces.

Long Edge Inserts

The long edge insert is capable of finish cutting of castings with a gate. Therefore, it is possible to reduce the number of cutting passes and to shorten the machining time as well.

Burr Prevention Inserts

The tool cutting edge angle is effective at reducing the thickness of chips, with almost no burrs generated in comparison to conventional products.

The finely-detailed R shape of the corner portion prevents chipping and enhances both stability and tool life.

Features of the Grades

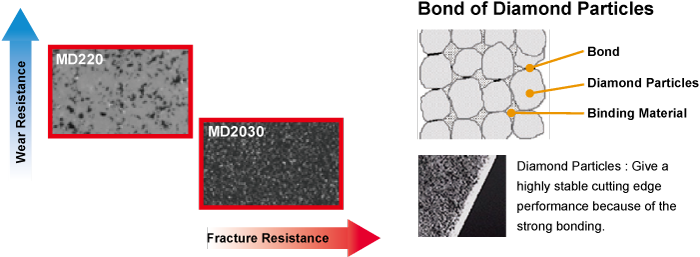

Diamond Sintered Segment Containing Ultra Microparticle Diamond

Features of MD2030

Intended for milling.

Improved fracture resistance when used in unstable applications.

The stability of the cutting edge can meet a wide variety of work material and cutting conditions.

Features of MD220

Sintered medium grain diamond particles. Wear resistance and fracture resistance are superbly balanced.

MD220 can prevent burr formation and achieve long tool life.

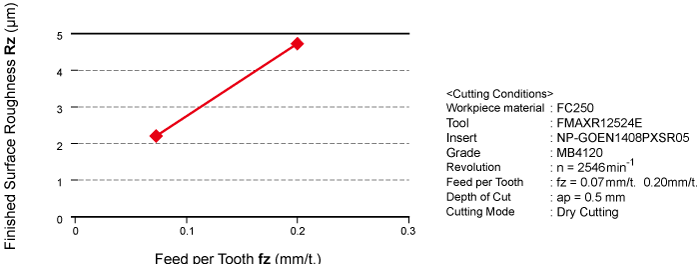

CBN Grade High Fracture Resistance

Features of MB4120

Fine CBN particles increase cutting edge toughness.

The high fracture resistance allows stable performance even during.

That grade prevent fracture, edge chipping and thermal clack not only for dry cutting but also for cutting under remaining coolant in previous process.

Cutting Performance

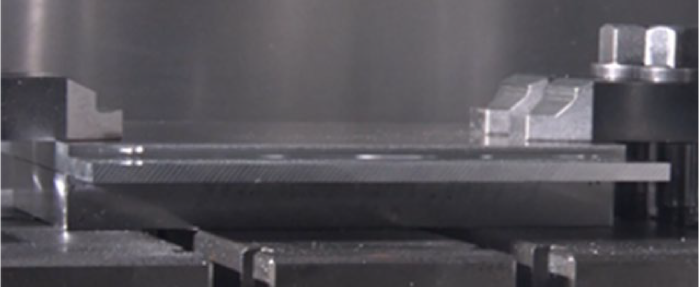

Surface Finish Comparison of Thin Plate Machining A5052

The new coarse pitch type FMAX lessens chattering and vibration and is ideal for producing a good surface finish on low rigidity set ups.

Workpiece Material: A5052 Diameter: DC=50mm Cutting Speed: vc=3140m / min

Feed per Tooth: fz=0.1mm / t. Depth of Cut: ap=2mm Width of Cut: ae=40mm

Cutting Mode: Dry Cutting

FMAX Coarse Pitch Type

Number of Teeth: 4 Feed per Tooth: vf=8000 mm / min

FMAX Standard Type

Number of Teeth: 10 Feed per Tooth: vf=20000 mm / min

Aluminium Alloy Finished Surface Roughness (Rz) Comparison by PCD Grade

Aluminium Alloy Effective Chip Disposal Range Comparison by PCD Grade

Gray Cast Iron Finished Surface Roughness (Rz) Comparison by CBN Grade

APPLICATION EXAMPLES

Technical consultation from here

24/7Contact form Japan

Japan United States

United States Mexico

Mexico Brazil

Brazil EU

EU United Kingdom

United Kingdom Germany

Germany Spain

Spain France

France Italy

Italy Poland

Poland Turkey

Turkey Czechia

Czechia China

China South East Asia, Oceania, South Africa

South East Asia, Oceania, South Africa India

India