AHX Series

General Purpose Multi Corner Insert Type Face Milling Cutter

Features of the Inserts

Unique 14 Corner Insert

Features of the Grades

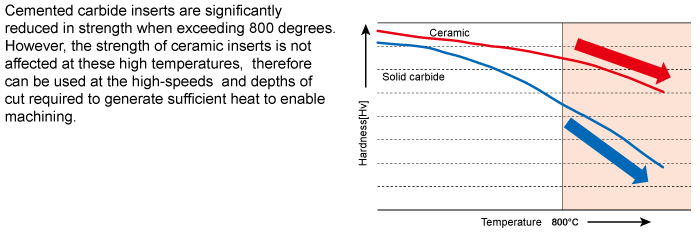

Coated Ceramic "XC5010"

The strength of ceramics allows for stable

machining even when cutting at high-speeds.

High Temperature Hardness of Cemented Carbide and Ceramic

Surface-smoothing Al₂O₃ coating suppresses the transmission of cutting heat

By applying an Al₂O₃ coating, which suppresses the transmission of cutting heat to the ceramic substrate, and together with a surface smoothing treatment, abnormal wear and adhesion of the workpiece material are suppressed.

Achieves 5 times the cutting length of non-coated ceramic grade when used at highspeeds

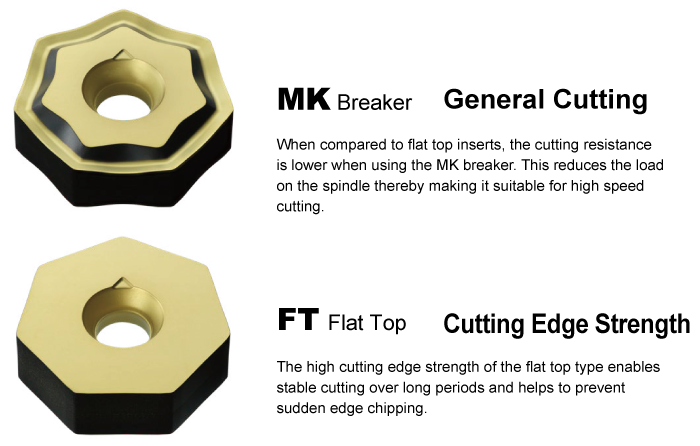

XC5010Chip Breaker System

The height setting when using MK inserts is different than when using FT type inserts.

FCD600 Finish Surface Comparison

A high quality machined surface is maintained even when high speed cutting conditions are used.

Coated Carbide Grade "MV1020/MV1030"

Newly Developed Al-Rich Coating

Advanced Wear and Thermal Shock Resistant

By adopting the newly developed Al-Rich coating technology, the (Al,Ti)N with a high Al content ratio displays a very high hardness. This greatly improves oxidation and wear resistance.

The extreme heat resistance of this new series achieves amazing stability not only during dry cutting, but also when wet cutting where inserts are usually prone to thermal cracking.

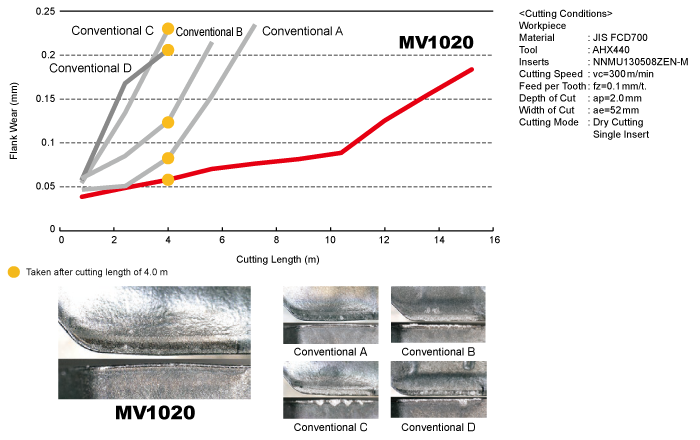

MV1020 offers overwhelmingly superior performance in high-speed cutting, and MV1030 achieves stable performance during interrupted and stainless steel machining.

Cutting Performance

Comparison of wear resistance when machining ductile cast Iron FCD700

Insert Grades for a Wide Range of Materials

Accumulated Al-Ti-Cr-N Based PVD Coating

TOUGH-Σ Technology

A fusion of the separate coating technologies; PVD and multi-layering realizes extra toughness.

Accumulated Al-Ti-Cr-N Based PVD Coating

Coated Carbide Grade "MC5020"

MC5020 has excellent wear, chipping and thermal crack resistance. These features prevent the problems usually associated with machining cast iron over prolonged periods.

Cutting Performance

Features of the cutters

AHX440S / AHX640S

A Unique Face Mill for

Machining of Steel, Stainless Steel and Cast Iron

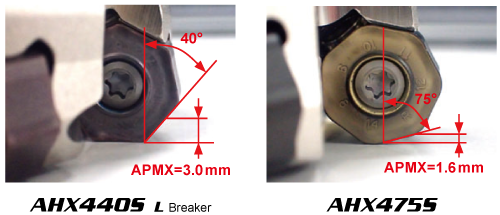

AHX475S

For High Feed Machining

High feed is possible with AHX440S by setting an RE = 3.2 mm insert to be used in a cutter body with a corner angle of 75° (KAPR15°).

The maximum depths of cut (APMX) will be limited to 1.6 mm.

AHX640W

For High Efficiency Machining of Cast Iron

Innovative Clamp System

New wedge geometry developed to increase the permissible number of teeth.

Unique wedge geometry uses a protruding section that fits inside the insert hole and acts as an Anti-Fly Insert (AFI) mechanism.

2 Variations for

Different Applications

Extra fine pitch and super extra fine pitch types allow high efficiency milling under various machining conditions.

Additionally, left hand types for use on special machines are also available as standard. Inserts can be used with both right and left hand type cutters.

Technical consultation from here

24/7Contact form

Japan

Japan United States

United States Mexico

Mexico Brazil

Brazil EU

EU United Kingdom

United Kingdom Germany

Germany Spain

Spain France

France Italy

Italy Poland

Poland Turkey

Turkey Czechia

Czechia China

China South East Asia, Oceania, South Africa

South East Asia, Oceania, South Africa India

India