MFE

Solid Carbide Flat Bottom Drills

High Efficiency Drilling in Various Types of Machining

High efficiency counter boring in various types of machining is with excellent chipping resistance.

Low cutting force provides less burr.

Excellent performance in correction of eccentric hole and cast hole due to high position accuracy.

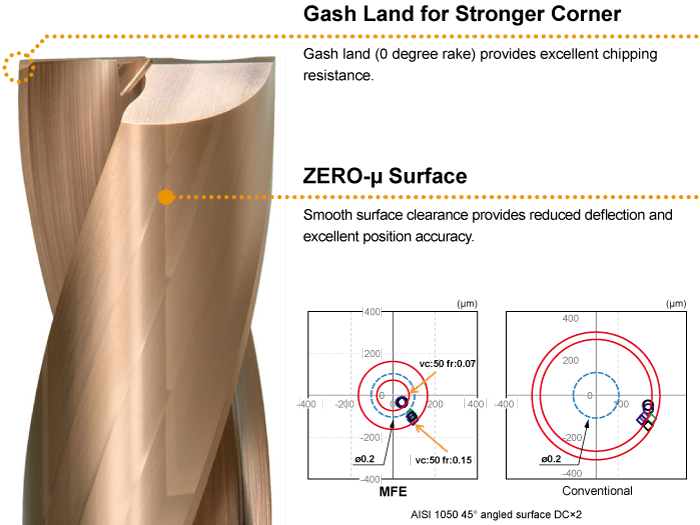

Features DC>3mm

Longer Tool Life with Stable Cutting

Coated Grade DP1020

Newly-developed coating for drills provides excellent wear resistance with low friction property, resulting in excellent versatility and extended tool life.

Features Small Dia. DC<3mm

Sharp Cutting Edges with Long Tool Life

Coated Grade DP102A

DP102A is a PVD coated cemented carbide grade specialized for drills, with greatly improved wear resistance when drilling small-diameter holes at low speeds and low feed conditions. This provides high adhesion and stability even with sharp cutting edges.

Cutting Performance

Comparison of Thin Plate Machining in AISI 4140

Flat tip angle prevents burr formation in various types of applications.

Comparison of Exit Burrs Generated in AISI 304

The unique cutting edge shape suppresses the formation of exit burrs.

Comparison of Fracture Resistance in AISI 1050

Achieved 1.3 times longer tool life compared to conventional products because of increased stability.

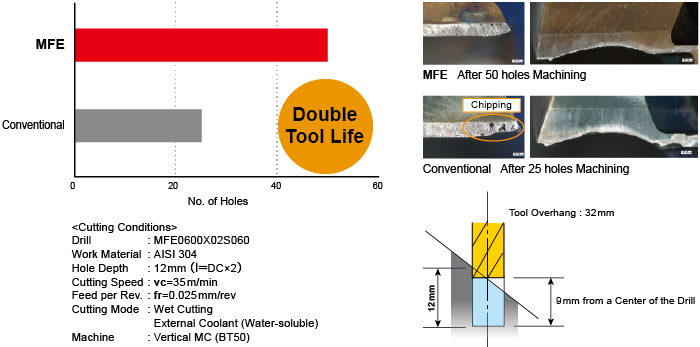

Comparison of Fracture Resistance in AISI 304

Achieved double tool life compared to conventional products because of the outstanding fracture resistance

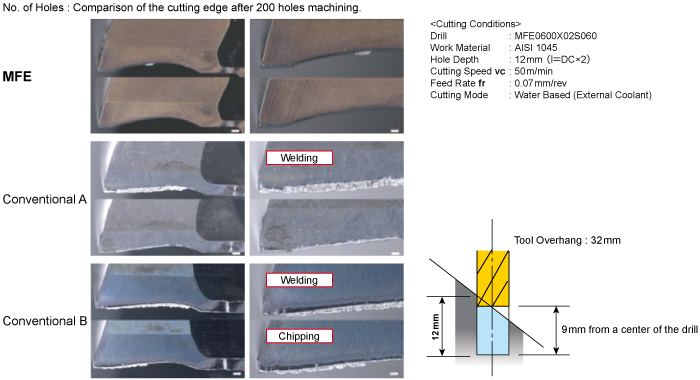

Comparison of Machining for Angled Surface with 45° Angle in AISI 1045

Controlled abnormal fracturing because of the excellent welding resistance properties.

Application Example

The above application examples are customer’s applications, so it can be different from the recommended conditions.

Technical consultation from here

24/7Contact form Japan

Japan United States

United States Mexico

Mexico Brazil

Brazil EU

EU United Kingdom

United Kingdom Germany

Germany Spain

Spain France

France Italy

Italy Poland

Poland Turkey

Turkey Czechia

Czechia China

China South East Asia, Oceania, South Africa

South East Asia, Oceania, South Africa India

India