![]() For steels

For steels

![]() For stainless steels

For stainless steels

![]() For cast iron

For cast iron

![]() For non-ferrous metal

For non-ferrous metal

![]() For difficult to cut material

For difficult to cut material

![]() For hardened material

For hardened material

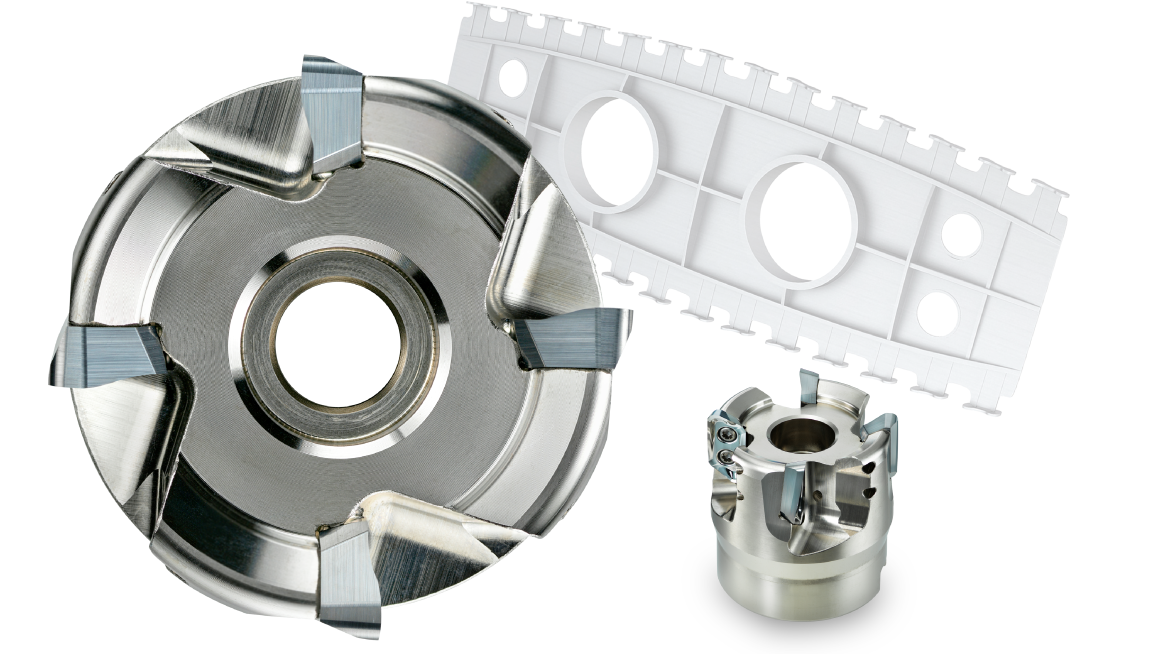

MITSUBISHI MATERIALS CORPORATION Metalworking Solutions Company (Company President: Tetsuya Tanaka, Address: Marunouchi, Chiyoda-ku, Tokyo) has released 10 items of the cemented carbide grade MT2010 for the AXD series for machining extra super duralumin and aluminium / lithium alloys.

The AXD cutter series enables high-speed and high-efficiency machining of aluminium by firmly fixing the insert to the body with two screws. It also uses a unique cutting edge geometry and advanced insert polishing technology to create a multi-functional cutter that achieves high-precision machining.

MITSUBISHI MATERIALS has developed the MT2010 cemented carbide grade insert for high-speed processing of extra super duralumin and aluminium / lithium alloys. It is a high grade cemented carbide but with excellent wear resistance and toughness, making it suitable for ultra-high cutting speeds of 5000m/min.

1. A high grade cemented carbide suitable for ultra-high-speed cutting speeds of 5000m/min that also has excellent wear resistance and toughness properties.

Additional Information: A clamp screw and insert kit (10 inserts, 20 clamp screws) that can be used with the AXD4000A are available. For safety reasons it is recommended to replace the clamp screws at the same time as the insert.

| Product name | AXD4000A cutter series, MT2010 insert grade: 10 Items | ||||||

|---|---|---|---|---|---|---|---|

| Release date | December 21st, 2020 | ||||||

| Standard Price (Distributor Model Number) |

|