VPX系列

高效加工用多功能铣刀

高强度、立装型铣刀上市

高负荷加工、斜面加工均可实现

TOUGH & MULTI

刚性极高、功能极多。

精心的设计,

改变立装型铣刀现状。

About TOUGH

追求立装刀片特有的强韧性。

About MULTI

解决多功能型铣刀相关课题。

可对应多种加工形态

Inserts

立装切削进步的4刃角型刀片。

适用于各种工件材料的刀片材料

MP6100/MP7100/MP9100 系列

TOUGH-Σ Technology

各种优异涂层、技术集大成(Σ),实现强韧(TOUGH)性。

铸铁加工用CVD涂层MC5020

MC5020是铸铁铣削加工用 第一推荐材料。

具备优异的耐磨损性,同时可抑制球墨铸铁加工时易发生的热龟裂、崩刃,实现长寿命。

断屑槽系列

新追加低切削阻力型断屑槽

使用实例

About TOUGH

Pursuing the tough machining characteristic of tangential blade inserts.

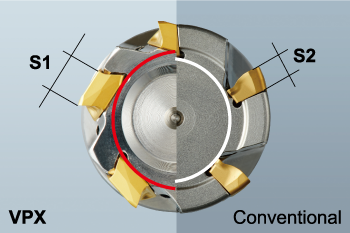

By arranging the inserts tangentially, high holder rigidity is secured. Also, because the part subjected to the highest loads during machining is larger (S1>S2), it has great fracture resistance and can be used without worry for high efficiency machining.

The wide seating surfaces provided allow the insert to clamp on more firmly. Suppresses deviation of the insert caused by vibrations during machining.

Comments from developersDurability born through repeated destructive tests.In order to improve durability, we began development by first applying a load to the cutter until it broke. After analyzing the reasons it broke, we produced an improved version then broke that as well. We repeated this process until we were satisfied with the results. As a result of this pursuit of durability through thorough destructive tests, we were able to come up with a cutter that is ideal for unmanned operation and high efficiency machining. |

About MULTI

Solving problems as a multi-functional cutter.

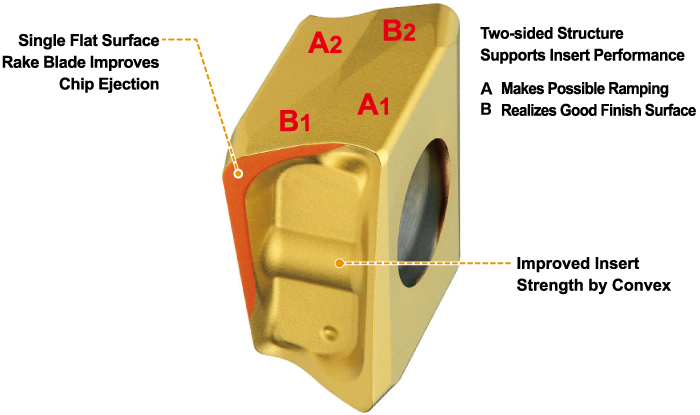

Comments from developersThrough trial and error, we’ve solved industry problems.The surface-to-surface balance of the insert is what allows the multi-functionality of ramping to be achieved, while maintaining the good chip ejection and the cutting performance inherent to tangential blade cutters. Most tangential blade cutters must be changed out with dedicated inserts for ramping. We made it a priority to unify these two styles of inserts, so as to avoid the trouble of managing two sets of inserts, and prevent installation mistakes.By focusing on the surface design of these new inserts, and through repeated trial and error, we were able to resolve one of the major issues in the industry. |

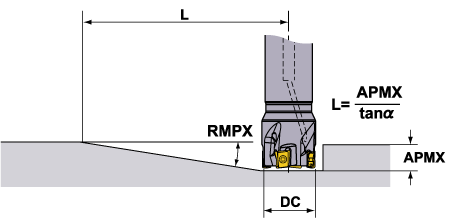

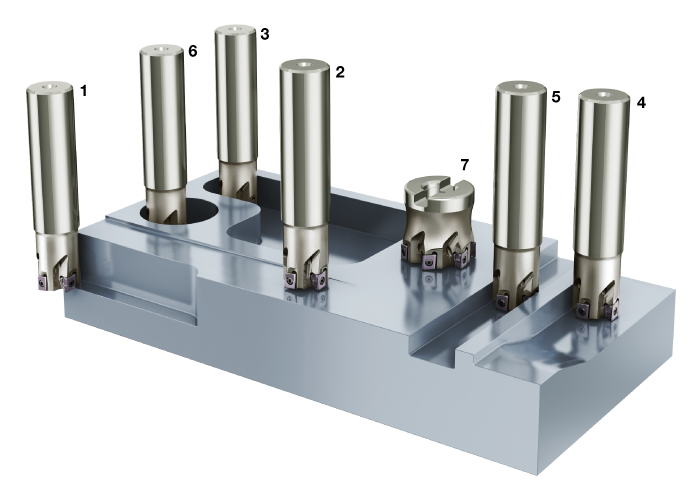

Different types of milling cover a wide variety of situations.

1. Shoulder Milling 2. Ramping 3. Pocket Milling 4.3-D Profile Milling

5. Slot Milling 6. Helical Milling 7. Face Milling

Inserts

Double-sided insert that has revolutionized tangential blade machining.

Comments from developersAn insert shape that was possible to design, but difficult to commercialize.The shape of the insert makes it tough while still enabling multi-cutting. It has been extremely difficult to move from the prototype, to maintaining a stable shape as a product. It is not an exaggeration to call this product, which has finally been commercialized through repeated improvements, the jewel of Mitsubishi Materials technology. |

High Wall Surface Accuracy

Large R-blades Achieve a Good Finish Surface

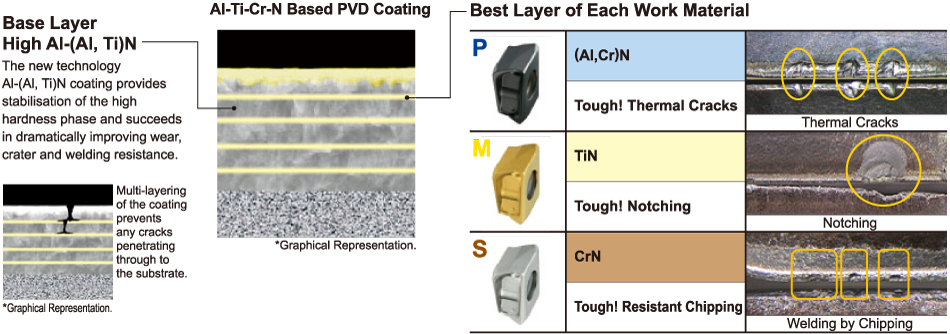

Insert Grades for a Wide Range of Materials

MP6100/MP7100/MP9100 Series

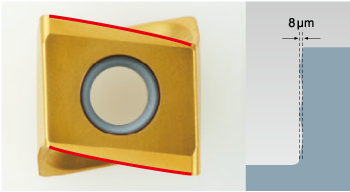

TOUGH-Σ Technology

A fusion of the separate coating technologies; PVD and multi-layering provides extra toughness.

CVD Coating MC5020

First recommendation for cast iron milling.

MC5020 has excellent wear resistance and also controls thermal cracking and chipping that are common when machining ductile cast iron.

Black Super-smooth Coating

Black super-smooth coating prevents abnormal damage such as weld chipping.

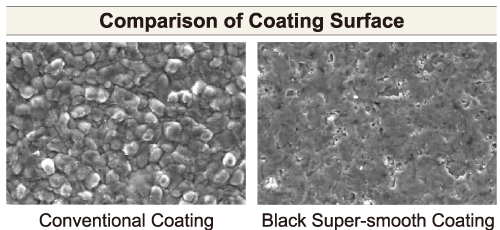

Chip Breaker System

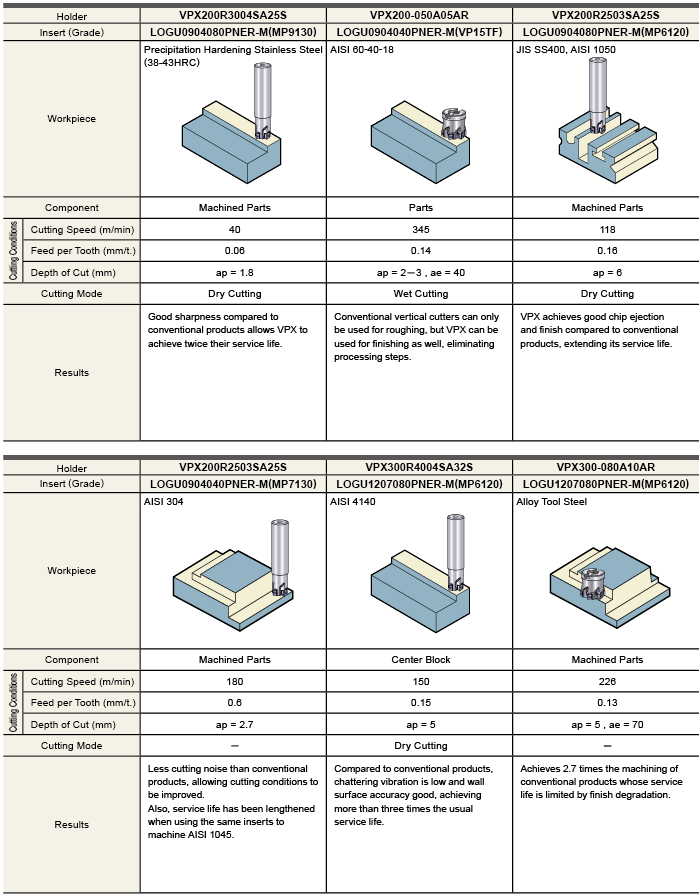

Application Examples

The examples shown are actual applications and can differ from the recommended cutting conditions.

请点击这里进行咨询

24/7咨询 日本

日本 美国

美国 墨西哥

墨西哥 巴西

巴西 EU

EU 英国

英国 德国

德国 西班牙

西班牙 法国

法国 意大利

意大利 波兰

波兰 土耳其

土耳其 捷克

捷克 中国

中国 South East Asia, Oceania, South Africa

South East Asia, Oceania, South Africa 印度

印度