![]() Aço

Aço

![]() Aço inoxidável

Aço inoxidável

![]() Ferro fundido

Ferro fundido

![]() Metal não ferroso

Metal não ferroso

![]() Material de difícil usinabilidade

Material de difícil usinabilidade

![]() Material endurecido

Material endurecido

Ideal conditions for cutting are short cutting time, long tool life, and high cutting accuracy. In order to obtain these conditions, selection of efficient cutting conditions and tools, based on work material, hardness, shape and machine capability is necessary.

Cutting speed effects tool life greatly. Increasing cutting speed increases cutting temperature and results in shortening tool life. Cutting speed varies depending on the type and hardness of the work material. Selecting a tool grade suitable for the cutting speed is necessary.

1. Increasing cutting speed by 20% decreases tool life by 50%. Increasing cutting speed by 50% decreases tool life by 80%.

2. Cutting at low cutting speed (20–40m/min) tends to cause chattering. Thus, tool life is shortened.

When cutting with a general type holder, feed is the distance a holder moves per workpiece revolution. When milling, feed is the distance a machine table moves per cutter revolution divided by the number of inserts. Thus, it is indicated as feed per tooth. Feed rate relates to finished surface roughness.

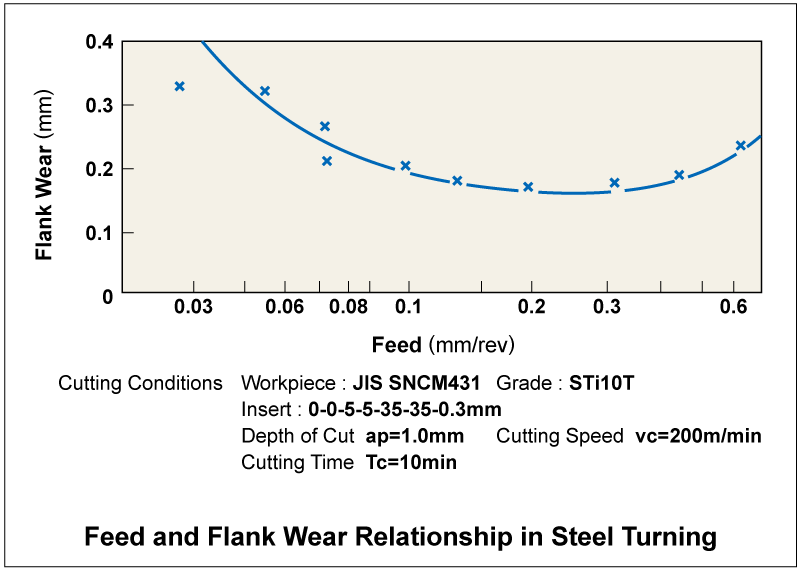

1. Decreasing feed rate results in flank wear and shortens tool life.

2. Increasing feed rate increases cutting temperature and flank wear. However, effects on the tool life is minimal compared to cutting speed.

3. Increasing feed rate improves machining efficiency.

Depth of cut is determined according to the required stock removal, shape of workpiece, power and rigidity of the machine and tool rigidity.

1. Changing depth of cut doesn't effect tool life greatly.

2. Small depths of cut result in friction when cutting the hardened layer of a workpiece. Thus tool life is shortened.

3. When cutting uncut surfaces or cast iron surfaces, the depth of cut needs to be increased as much as the machine power allows in order to avoid cutting impure hard layers with the tip of cutting edge to prevent chipping and abnormal wear.

Fale conosco

Formulário para contato Japão

Japão Japão

Japão Estados Unidos

Estados Unidos México

México Brasil

Brasil EU

EU Reino Unido

Reino Unido Alemanha

Alemanha Espanha

Espanha França

França Itália

Itália Polônia

Polônia Turquia

Turquia Tchéquia

Tchéquia China

China South East Asia, Oceania, South Africa

South East Asia, Oceania, South Africa Índia

ÍndiaOs cookies necessários são usados para ajudar este site a funcionar corretamente.

Por exemplo, eles fornecem a funcionalidade de retenção de login.

Os cookies analíticos coletam informações sobre seu uso deste site de forma anônima e agregada. Esses cookies são usados para analisar e melhorar a funcionalidade deste site.

Esses cookies permitem que este site forneça funcionalidade e personalização aprimoradas. Eles podem ser definidos por nós ou por terceiros.

Os cookies funcionais são usados por serviços de redes sociais para rastrear o uso de seus recursos integrados. Por exemplo, esses cookies permitem que você compartilhe páginas deste site com sua rede social.

Os cookies de publicidade podem ser definidos através deste site por nossos parceiros de publicidade com base nos dados obtidos. Eles identificam seu navegador e dispositivo de internet exclusivos e podem ser usados para fornecer dados demográficos anônimos, criar perfis de seus interesses e exibir publicidade relevante a esses interesses.

![]() Aço

Aço

![]() Aço inoxidável

Aço inoxidável

![]() Ferro fundido

Ferro fundido

![]() Metal não ferroso

Metal não ferroso

![]() Material de difícil usinabilidade

Material de difícil usinabilidade

![]() Material endurecido

Material endurecido

![]() Acabamento

Acabamento

![]() Usinagem média

Usinagem média

![]() Desbaste

Desbaste