DLC4LATB / C4LATB

Fresas de topo esférico cônico para rotores de alumínio

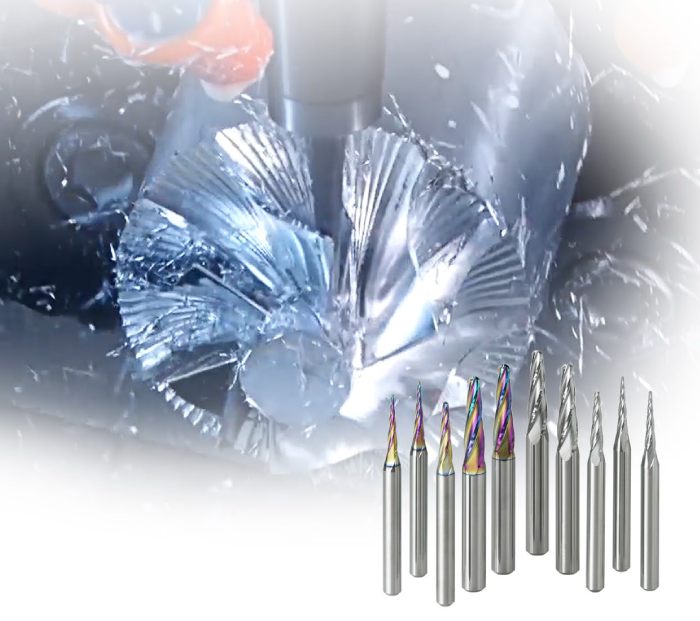

Rigid Design and New DLC Coated Type for High Efficiency, Reliable Machining of Aluminium Impellers

Feature

Featuring 4 peripheral flutes for strength and rigidity but with only 2 ball end flutes for superior chip discharge.

The uniquely developed DLC coating provides excellent welding resistance during high speed machining and when the coolant supply is reduced. Additionally, the low coefficient of friction reduces cutting resistance.

Application Example

High Efficiency Machining of Aluminium Alloy Impellers

Excellent high depth of cut and feed.

Cutting Performance

Slotting with a Limited Coolant Flow Rate

Resistance to welding prevents tool breakage when coolant supply is limited due to the geometry of the workpiece.

This test was performed with a limited coolant flow rate. If the coolant flow rate is sufficient, non-coated end mills can also be used.

Please inquire with us regarding special items.

Case Examples for Non-standard Shapes

Fale conosco

Formulário para contato

Japão

Japão Estados Unidos

Estados Unidos México

México Brasil

Brasil EU

EU Reino Unido

Reino Unido Alemanha

Alemanha Espanha

Espanha França

França Itália

Itália Polônia

Polônia Turquia

Turquia Tchéquia

Tchéquia China

China South East Asia, Oceania, South Africa

South East Asia, Oceania, South Africa Índia

Índia